One of the most popular things that I have done and blogged about is the Ranque Hilsch Vortex Tubes that I built. I get a lot of emails asking a lot of questions about RHVT’s and how to build them. There are no easy cut-and-dry answers to most of these questions because there are so many variables involved when building one, but there are some generalizations that can be made. Recently I decided to put together a FAQ page and with the help of a colleague and on line collaborator: Théo M. we have tried to answer some of the questions people have asked me. I am not at all an expert on these things and only know what I know by reading information online and from my own experiments. If you are planning on building one of these please look around at all the information the net has to offer and by all means contact me if you have any questions. At the end of this post I have placed some links that I have found useful.

As always when working with anything potentially dangerous (like compressed air) always wear appropriate protective gear like safety glasses and know what you are doing. If there are any questions that you may have that are are not in this FAQ or not answered clearly please email me at ottobelden@yahoo.com or leave a comment and I’ll be happy to answer you!

|

| Homemade Vortex Tube Instructions from THIS post |

If I get more questions in emails and comments on my blog I'll answer them below in this post and update the date below. I'll highlight any new info in the post so it will be easy to find.

FAQ UPDATED: 7/21/11

Check back often if you are curious or after you ask me a question. I'll answer you directly and add your question and answer to this post. Continue reading for the FAQ's and links!

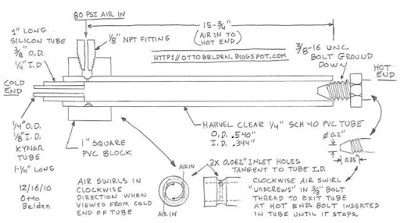

As a place to start when thinking about building your very own Ranque Hilsch Vortex Tube, I've compiled some "rules of thumb" that I have used when figuring out what materials to use when I build a tube. This list is based on what I have read and experiments I have done. "Experiments' in this case means stuff I've built that didn't work too well. Have a look at these "rules" before reading the below FAQ's.

1) Start with a tube Inner Diameter that is convenient and relatively small – 5/16” is a good place to start. Choose a tube material that is a thermal insulator if possible like plastic. Keep in mind that the bigger the tube the bigger the compressor you will need.

2) As a starting point make the hot end of the tube about 45 times the tube ID – this is a general place to start, shorter can work too but I start with a longer tube. After all you can always cut it!

3) The cold air orifice should be about 0.50 the tube ID. Like everything else this is negotiable but 1/2 the tube ID has worked well for me. If possible make this part easy to remove so you can change it and see what happens.

4) The inlet nozzles are more or less about 0.11 the tube ID. How many and actually even how big they are depends on how much air you can deliver without losing pressure. You have to consider the total area of all the nozzles and more nozzles is better so having one big one wouldn't be as good as several smaller ones. See the question below "How many inlet orifices is best.." What is important is that the nozzle(s) are tangent to the tube ID. You want them tangent so the air goes into the tube 'spinning' around the inside wall. have a close look at the above diagram. A very slight angle towards the hot end doesn't hurt either.

5) The cold air end of the tube should be no longer than 10 times the tube ID. You actually don't even have to have a cold air tube on the end just make sure there is little or no back pressure. There is a lot written about the cold tube in the literature and the best tube I built didn't really have a cold air tube. Check out the picture above.

6) The vortex chamber can be bigger than the tube ID if there is a smooth transition between the two but it can also be the same size as the ID of the tube. Some researchers have found that making the inlet area a bigger ID and transitioning down like a funnel eventually reaching the tube ID works well. That is a tricky shape to make with garage tools so I don't bother.

7) The 'cold valve' at the end of the hot end should be tapered and with a dull point. A concave point can work better sometimes too and the position of this valve relative to the end of the tube should be adjustable - it's a valve after all! I have found that a tapered cylinder with a dull bullet shaped end works good. Make this part removable so you can take it off and either cut down the long end (see 2 above) or try different shapes. Some people have even drilled a hole in the end to let the cold air out co-axially with the hot air. In the diagram above I used a bolt, the spinning vortex air 'unscrewed' in the bolt threads.

|

| My Vortex Tube photographed with a Thermal Imaging Camera From THIS video |

Q – How does a Ranque Hilsch Vortex Tube work?

A – I’m not sure! Actually there seem to be competing theories as to what is going on inside that makes it do what it does, but what does it do? A Ranque Hilsch Vortex Tube is a device with no moving parts that you put air into and get air out one end that is colder than the air you put into it, and the other end has air hotter than the air you put into it. So in some way the RHVT is separating the inlet air into two outlet streams, one hotter than the inlet and one colder. Really cool if you think about it!

Q - How much cold air will I get and what temperature will it be?

A - Vortex tubes are better coolers than heaters, in fact isentropic efficiency is maximum when the cold air fraction is about 0.7 or 0.8 and the Ranque-Hilsch effect is increased at high cold fraction values. In other words the cooling / heating effects will change depending on the ratio of inlet air flow / cold air (cold air fraction). The lower the cold air fraction the greater the cold air temperature drop will be and the lower the hot air temperature rise will be generally.

Q - How ‘big’ of a compressor is necessary to run a RHVT?

A- There is no easy answer to this question because there are so many variables but generally as the tube diameter gets larger the amount of air flow required goes way up. So for a big tube cooling and heating a lot of air you will need a big compressor capable of delivering a large volume of air without the pressure dropping. Looking on line at commercially available tubes will show you that you need at least 2 SCFM at 100PSIG or more. Also look at number 4 in the 'rules of thumb' above.

Q- What is the coldest temperature air I can expect to get from a RHVT?

A- Another way to ask this question is what temperature drop or rise might I expect to get below (or above) the inlet gas temperature. This depends on how good of a tube you have built and what the cold air ratio is. If you have been reading this entire post you'll know by now that this depends on a lot of factors.

Q – How can I adjust the cold air ratio?

A – The cold air ratio is usually adjusted with the cold air “cone valve” or similar “plug” near the hot end of the tube. This valve is usually shaped like a cone although other shapes have been used and adjusting it in and out changes the amount of hot air that is released from the tube – which changes how much cold air is released too. Because the cone valve is shaped like a cone pushing it into the tube reduces the area around the cone that is open (the annulus) and you get less hot air out.

Q - Can the temperature of the cooler air be regulated?

A- Sure it can! Just change the cold air ratio by opening or closing the cone valve. See the above question “How can I adjust the cold air ratio?”

Q - What tube outer diameter should I use?

A – The outer diameter of the tube isn’t important, the inner diameter is what is important. Have a look at the “rules of thumb” at the top of this post. An insulated tube might make the OD bigger but other than that it doesn't have much of an effect.

Q - What should the tube be made of?

A - Anything will work for the tube but usually a material that is a good thermal insulator is better for the performance at least in my experience. Plastic works good because it's easy to work with and you can usually find more sizes so finding something that is right for what you are building is easier.

Q – How many inlet orifices is best for a tube about 3/8” ID?

A - The number of inlet nozzles and their diameter can have a big impact, the more inlets the better to a point. The Ranque-Hilsch effect is based on the difference in kinetic energies and fluid particles have different velocities if the inlet nozzles are narrow enough. The most successful tube that I built had an ID of about 11/32” and it used 2 inlet orifices. Have a look at THIS post and the dimensions, as well as the video I made if the construction! Also look at 4) of the "Rules Of Thumb" above.

Q- How can I calculate the size of the vortex tube to suit the amount of cooled air needed?

A- I would approach this question by going on line and looking at the commercially available RHVT that are available for purchase and use them as a reference. There is quite a bit of data out there that shows the size of the tube, the air requirements, the BTU’s / Hour, and the Temperature drop for various cold air fraction ratios. I would find one on line that looked like it would satisfy my needs and then make the decision to either buy it or try to make it or something similar myself.

Q - Can I use a RHVT to make ice cream or cool my house?

A - Yes! And if you do email me pictures, I'd like to see them!

Q - Because the tube is taking air of one temperature and making hotter and colder air is it creating energy?

A - No I don't think it is. The laws of physics and the natural order of the universe prevent this sort of thing. If you look at how much energy you are expending compressing the air vs. how cold / hot the air is coming out you will realize that you are loosing a lot of energy, not creating it. But if you do manage to create energy with a RHVT contact me immediately, I want to talk to you.

Again if you have any questions please leave a comment or send me an email at ottobelden@yahoo.com

Links:

This first link more info in it than you will ever need. It starts out in a foreign language but the text is in English.

Here is a site that has lots of info from a guy that makes his own tubes. Be sure to check this out and for sure look at his links page for info

A how to video of me building a tube, the best instructions on the net IMHO

Here is a paper that helped me a great deal when building and understanding RHVT's

UPDATE 7/21/11: Here is a link to a video of some engineering students that built a tube based on my first design. LINK Here is a link to my first design LINK

The hole size of cold end(2mm) is much smaller than hot end(8mm), it causes the air come out is not cold anymore. Is there any solutions that I can do?

ReplyDeleteThanks for your help.

seanchang,

ReplyDeleteI would have to know more about the tube you are talking about. Have you built a vortex tube? Does the tube you are working with have a 'valve' or adjustment on the hot end? Give me some more details and I might have some suggestions.

Thanks for checking out my blog, I'm happy to help you if I can!

- Otto

your works are awsome.......can i know a transparent material which can be used instead of pvc pipe?

ReplyDelete