Moving forward with the creation of the robot I spent some time this weekend building up more components for the remaining three legs that I'll need. Most of the time was spend duplicating the two main metal parts needed for each leg. I have decided to call one of them a horse and the other a swan - sounds odd but that is what they look like! The horse plates I made out of 0.03" aluminum plate as they don't add much to the rigidity of the leg itself. The initial prototype leg has the same horse part made from 0.06" thick plate but I think that is thicker than it needs to be. Just to save a small amount of weight and to make the fabrication a bit easier I went with the 0.03" Figure out which ones are the horse and swan from the pictures, there will be extra points for folks who guess correctly! Also included in the pics is the first prototype to give an idea as to how each new piece will fit into the leg.

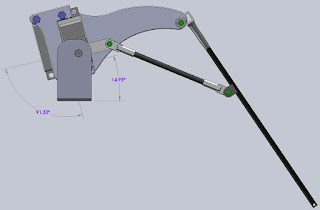

Also the carbon tubes for the legs and the bearing joint connections had to be constructed. For the top ends I cut three pieces of plastic Knex parts, drilled a hole through them and put in a 4-40 socket head cap screw. There is one partly assembled at the top of the picture above. I screwed the screw into the end of the carbon fiber tube with some Weld-It glue, looped some wire through it as well, wrapped it with fishing line and put some heat shrink over it. This is the same way I made the first prototype and it made a strong connection.

In a similar fashion I connected the middle leg joint plates. They are made from 0.03" AL that I bent at 90 degrees. I sanded the outside of the carbon tubes in the area where the plates will be joined and glued them with the Weld-It. Once the glue had dried for about 20 min and the plates were somewhat secure I applied more glue over the outside of the carbon tubes and plates then wrapped them with fishing line, getting it really wet with the glue. Over the fishing line and the glue went some heat shrink tubing. Heating the tubing with the weld-It glue still wet causes it to 'carmelize' a bit and turn the gooey mess into a hard solid mass. This also is what i did with the prototype and it is suprisingly strong.

Taking a break from building the legs I dug part of an old color Epson printer/scanner out of the junk pile. I took the broken printer apart a few months ago and threw away most of it, saving the top cover, the glass you set your page to be scanned on, the power supply and all the beat motors, belts and gears that were inside. I'll use it all up on other projects someday.... but today I took the top cover off that used to close down on top of the glass to cover a page being scanned. I figure that this will make a rigid and light base undercarriage to mount the legs on once I get them all built. It is bigger than I needed so i cut it down to about a 7" square on the bandsaw and sanded the edges clean.

There are some other washer spacers that I have to make that are also 0.03" AL with a 0.14 hole in the center and an outed diameter of 0.25" - these are a pain and I was getting tired so I just made 4 so I could assemble a second leg. At this point I have two complete legs built with 2 Futaba s3004 servos in each leg. I have two more servos right now and I'm going to build up the turn mechanisms now for these two legs before I move on to the remaining legs.

I'm getting close to needing to figure out what control system I'm going to use to animate the robot. About the same time I'll have to work out the walking coordination that is required by the linkage system. I wrote briefly about this in the previous post and in thinking about it I believe there is an easy way to do it. I still have some time as there is a lot to do before the legs are ready for a brain....